We have worked with some of the largest agricultural processors in the world that purchases crops to process food ingredients, animal feed ingredients, renewable fuels, and naturally derived alternatives. Specific equipment applications required the automation of cooking/pressure vessels, augers, load cells, railcars (integration to), dry ingredient bins, pumps, and heat exchangers.

Odyssey Controls provides solutions to a large Western New York full-service agribusiness that has been in operation for over 90 years. The following products/services are offered: dry and liquid fertilizers mixing, crop protection products, ag lime, gypsum, seeds, custom application and spraying, fine ground corn meal mixing, and corn purchasing.

With over 25 years of experience working with the largest manufacturer of Fiber Optic glass and cabling in the world, our teams have extensive knowledge of Facility Equipment and Control Systems required for these plants. Our group has supported R&D and production facilities throughout the world using numerous control system platforms. Everything from the delivery of raw materials for the process to the control of air/water pollution abatement systems have been automated.

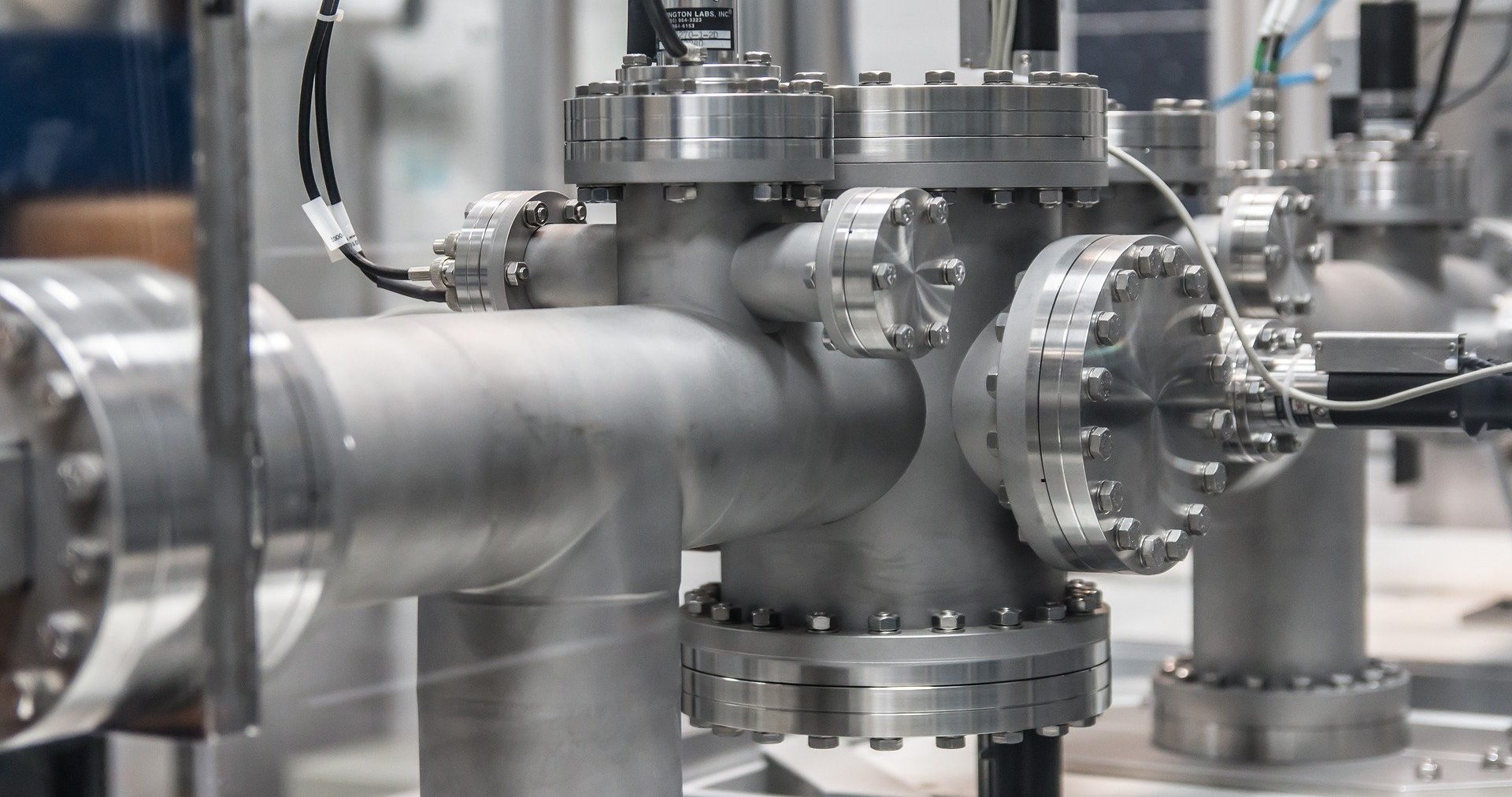

We have worked on both industrial and municipal water/wastewater treatment plant control systems for many customers in domestic and foreign markets. Water facilities have included equipment such as remote pumping stations, chemical dosing systems, carbon filtration skids, distribution piping, valve control, slow sand filter beds, rapid filters, storage tanks, residual chlorine sensing, supply/delivery pump stations, and RO/DI units (industrial). Wastewater facilities have included equipment such as lift pumps, bar screens, sedimentation/aeration tanks, incinerators, clarifiers, disinfection tanks, UV systems, and discharge controls.